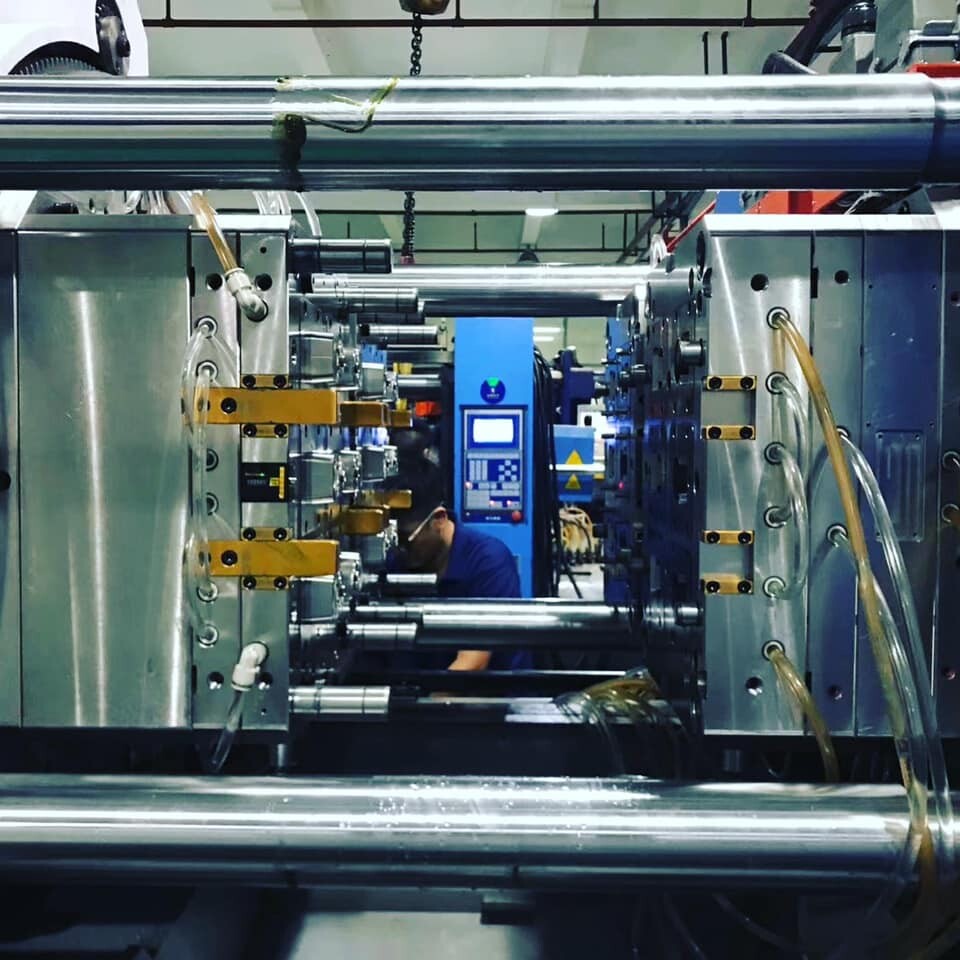

To decide to buy an injection mold can easily be complicated, as a result of the considerable amount time which is to be expected between purchaser and contract manufacturer prior to the final merchandise may be chose. Even so, the pursuing points can help you preserve an excessive amount of period and help to make the progression noticeably a lot easier.

- Set up a descriptive require for plans

Though plastic mold makers are highly proficient, they can browse thoughts. In this point, it is usually crucial that you involve all of the linked facts, which includes the amount of cavities, the metal, the estimated life-time of the mold, and virtually any warranties you may possibly need. The mold griddle will response any problems you may possess that help you consider what is definitely very best for your criteria. The more exact your RFQ Is certainly, , the more appropriate the estimate will probably be.

- Open with your thinking for a price

Setting up a complete quotation for a overall goal may necessitate a good deal of work and it would unproductive to waste the moldmaker’s time at the time you would not want so much depth, or when you simply won’t possibly invest in them.

- Not to infringe the intellectual property

When your moldmaker creates tips, all those choices will be their intellectual property and you should not take on those ideas to a new moldmaker and have them to produce it in your case.It is strongly advised that you consider additional people’s recommendations into account ahead of finally deciding on a mold manufacturer. Not simply can be it hard to make use of someone else’s suggestions, but it surely may also even trigger dilemma with the last mold developer, who could possibly not really comprehend exactly for what reason those ideas had been produced in the initial place.

- Relationship with your mold developer

Also, when you continue in close interaction with your moldmaker with regards to finances, time, and component volume, it will be easy to perform enhanced benefits after some time.

- Talk to the mold manufacturer through the total course

Moldmakers will certainly give regular advancements information on their jobs, and so you can constantly stay up to date. It is certainly also significant that you should be knowledgeable of any alterations occurring to your task, thus if you want even more details, be sure you request to ensure that you can put your mind confident.

- Be sure you at all times pay out by the due date

Moldmakers need in advance payments for expenditures, therefore discuss to them on the subject of an set up that is effective for you both. A variety of moldmakers will give diverse ideas for payments, thus make a payment routine that will work for you both.

- Your product layout modification

Reforming the injection mold might imply reforming your component design and style.The injection mold will more than likely ought to be adjusted once your product layout adjustments.Swapping the style of your component might involve reforming the injection molds themselves.

- Be aware of your mold arriving date

A finalization schedule deviates based on the extent of the task: it may be once the transaction is finished, or whenever you get a test component, or once the last item is delivered out. Typically, an injection molding task is regarded as finished after it is prepared for creation of the component designed.

Moldmakers will more often than not take minor modifications to the end of the procedure to help make the component to design measurements. If the measurement alter late into the operation, the injection mold might nonetheless be regarded as finished,any future modifications will have to be handled via an engineering modify order, or ECO.

- A low-cost article incorporates a reason

It’s worth the cost to spend a great amount for high-quality craftsmanship, instead of acquiring stung with a mold that doesn’t fulfill your requirements for China injection molding; you will find some other moldmakers that provide discount rates since they have attempted to reduce expenses on their own.

Based on the outdated saying, the excellence of an injection mold is straight associated to the excellence on the components you create, so select a mold that meets your requirements prior to one does so.